Classical Mechanics and the Atwood Machine

The Historical Development of the Atwood Apparatus

The Atwood machine, conceptualized by the English physicist and mathematician George Atwood in 1784, represents a seminal advancement in the experimental verification of Newtonian physics. During the late eighteenth century, the primary challenge facing researchers was the difficulty of accurately measuring the acceleration due to gravity, ##g##, because free-falling objects moved too rapidly for the primitive timing devices of the era. Atwood designed his apparatus to dilute the effect of gravity by connecting two unequal masses via a pulley, thereby slowing the motion to a degree that could be observed and recorded with high precision. This innovation allowed for the direct observation of constant acceleration and provided the empirical evidence necessary to solidify the laws of motion that Isaac Newton had proposed decades earlier. By providing a controlled environment for the study of dynamics, the Atwood machine became a cornerstone of scientific education and remains a fundamental tool for demonstrating the relationship between force, mass, and acceleration in modern physics laboratories.

On This Page

We Also Published

Atwood's original design was remarkably sophisticated for its time, incorporating a system of light wheels with small moments of inertia to support the axle of the main pulley, effectively minimizing the impact of friction on the experimental results. This attention to detail ensured that the observed acceleration would closely match the theoretical predictions derived from the second law of motion. The device was described in detail in his 1784 publication, A Treatise on the Rectilinear Motion and Rotation of Bodies, which served as a comprehensive textbook on mechanics. Beyond its pedagogical utility, the machine played a critical role in the historical transition from qualitative natural philosophy to quantitative experimental science. It allowed researchers to move beyond simple observations of falling bodies and engage with the more complex dynamics of coupled systems, where multiple forces interact through mechanical connections. Today, we recognize the Atwood machine not just as a historical curiosity but as a perfect mathematical model for understanding Connected Bodies in Tension and the underlying symmetry of mechanical systems.

The impact of this machine on the scientific community was immediate and profound, as it offered a way to test the proportionality of force and acceleration across various mass ratios. By adjusting the difference between the two suspended weights, Atwood could vary the resulting acceleration from nearly zero to values approaching free fall. This flexibility made it possible to conduct a wide array of experiments that validated the mathematical structures of classical mechanics. In the context of modern education, the machine serves as an introductory bridge to the concept of simultaneous equations and vector analysis. It forces students to consider the system as a whole while simultaneously isolating individual components, a mental exercise that is essential for mastering advanced engineering and physics problems. The elegance of the device lies in its simplicity; with just a string, a pulley, and two masses, it unlocks the profound mysteries of the physical universe and provides a platform for solving complex numerical problems like the one addressed in this technical overview "".

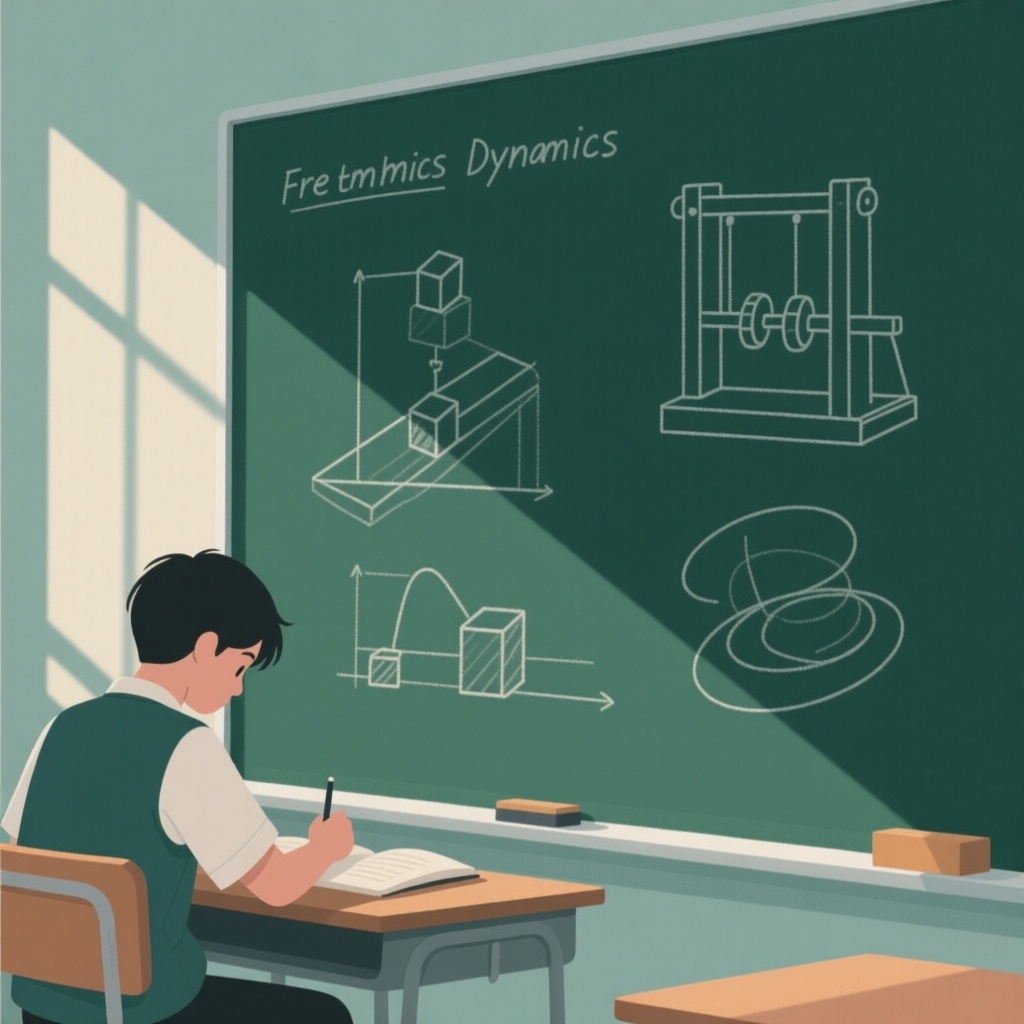

Theoretical Foundations of Newtonian Dynamics

To analyze the behavior of an Atwood machine, one must first master the fundamental principles of Newtonian dynamics, specifically the second law of motion. This law states that the net force acting upon an object is equal to the product of its mass and its resulting acceleration, expressed mathematically as ### \sum \vec{F} = m \vec{a} ###. In the context of connected bodies, the forces involved are typically gravitational pull and the tension within the connecting medium. Gravity acts vertically downward on both masses, while the tension in the string acts upward, opposing the weight of the objects. When the masses are unequal, the imbalance in gravitational forces creates a net force that drives the system toward the heavier side. This scenario requires a meticulous accounting of all vector components to ensure that the signs of the forces and accelerations are consistent across the entire system. Understanding these dynamics is crucial for predicting the behavior of any machine where mechanical power is transmitted via cables or belts.

Central to the theoretical framework of this problem is the concept of a system. Rather than viewing the two masses as isolated entities, we treat them as a single dynamical unit connected by a constraint. This constraint is the inextensible nature of the string, which dictates that the distance moved by mass one must be identical to the distance moved by mass two within the same timeframe. Consequently, the magnitude of the acceleration for both masses must be equal, although their directions are diametrically opposed. This realization simplifies the mathematical modeling of the system by reducing the number of independent variables. Furthermore, the assumption of an ideal pulley—one that is both massless and frictionless—implies that the tension is uniform throughout the entire length of the string. In a real-world scenario, the pulley's rotational inertia and the friction within its bearings would consume a portion of the available energy, but in this theoretical analysis, we focus on the pure Newtonian interaction of mass and gravity.

The tension in the string is an internal force that arises as a reaction to the external forces acting on the connected bodies. While gravity pulls the masses toward the Earth, the string exerts an equal and opposite force on each mass at the point of contact, preventing them from falling at the full rate of ##g##. The tension effectively transmits the weight of one mass to the other, creating a tug-of-war dynamic that determines the equilibrium or motion of the system. For a system released from rest, the acceleration is governed by the ratio of the net force (the difference in weights) to the total mass of the system. This relationship provides a clear illustration of how inertia resists changes in motion. By studying these interactions, we gain a deeper appreciation for the mathematical elegance of classical mechanics and the precise way in which forces are distributed within physical structures. This theoretical base allows us to move forward into the rigorous derivation of the specific values for acceleration and tension required by the problem statement.

Theoretical Analysis of Connected Bodies in Tension

Tension Vectors and Force Distributions in Coupled Systems

In the study of dynamics, the term tension refers to the pulling force transmitted axially by means of a string, cable, or chain. In the Atwood machine, tension is the primary mechanism through which the two masses interact. When mass two, ##m_2##, is greater than mass one, ##m_1##, it tends to descend due to the larger gravitational pull acting upon it. As it moves downward, it pulls the string, which in turn pulls mass one upward. Because the string is light and passing over a frictionless pulley, we can assume that the magnitude of the tension force, ##T##, is constant at every point along the string. This leads to a symmetrical force distribution where mass one experiences an upward force of ##T## and a downward force of ##m_1 g##, while mass two experiences an upward force of ##T## and a downward force of ##m_2 g##. The net force on each mass is determined by the vector sum of these opposing forces, which then dictates the direction and magnitude of the system's acceleration.

The representation of these forces using vector notation is essential for maintaining mathematical rigor during the derivation process. For mass one, which accelerates upward, we define the upward direction as positive. The equation of motion for this body becomes ### T - m_1 g = m_1 a ###. Conversely, for mass two, which accelerates downward, we define the downward direction as positive to maintain a consistent coordinate system following the path of motion. This leads to the equation ### m_2 g - T = m_2 a ###. It is critical to note that the acceleration ##a## is the same for both masses because they are coupled by the string. If the string were to stretch or break, these equations would no longer hold, as the kinematic constraint would be lost. The tension ##T## acts as the coupling agent that ensures the two masses behave as a singular mechanical system, reflecting the connected nature of the problem. This methodology of isolating each body while accounting for their interaction is a standard practice in mechanical engineering and structural analysis.

The distribution of force within the system also has implications for the support structure of the pulley itself. While the tension ##T## acts on the masses, it also exerts a downward force on the pulley. Since the string wraps around the pulley and pulls downward on both sides, the total force exerted on the pulley's axle is approximately ##2T##, assuming the string segments are parallel. This is known as the thrust on the pulley. In technical applications, such as the design of cranes or elevator systems, engineers must ensure that the pulley and its mounting can withstand this combined load. By calculating the tension and acceleration for a specific set of masses, we can determine the stresses within the materials and the safety margins required for the system. This problem, featuring masses of ##4 \text{ kg}## and ##6 \text{ kg}##, provides a perfect numerical example to demonstrate how these theoretical force distributions translate into quantifiable physical quantities that can be used for engineering design.

The Role of Inextensible Strings and Ideal Pulleys

The reliability of the calculations in an Atwood machine problem depends heavily on the assumptions of an inextensible string and an ideal pulley. An inextensible string is one that does not change its length regardless of the tension applied to it. This property is vital because it ensures that the velocity and acceleration of the two connected masses are identical in magnitude at every instant. If the string were elastic, like a rubber band, the two masses would undergo oscillatory motion relative to one another, significantly complicating the differential equations required to describe the system. In most introductory and medium-difficulty physics problems, the string is also considered massless. This simplification means we do not have to account for the shifting weight of the string as it moves from one side of the pulley to the other, which would otherwise result in a time-dependent acceleration. These idealizations allow us to focus on the primary dynamics of the masses themselves.

The ideal pulley further refines the model by removing sources of energy dissipation and rotational inertia. A frictionless pulley ensures that there is no resistive torque opposing the motion of the string, which allows the tension to remain uniform on both sides. In a real pulley, the tension on the descending side would be slightly higher than the tension on the ascending side to provide the torque necessary to overcome friction and accelerate the pulley's own mass. However, by assuming a massless and frictionless pulley, we stipulate that no net force is required to rotate the pulley itself. This simplification is mathematically elegant because it allows the tension ##T## to be treated as a single scalar value in our system of equations. This level of abstraction is necessary for establishing the fundamental laws of motion before introducing the complexities of Real-World Mechanics where friction and inertia must be quantified through more advanced methods like the moment of inertia and coefficients of friction.

When these assumptions are combined, they create a highly constrained system where the motion is purely determined by the masses and the local gravitational field. This makes the Atwood machine an excellent tool for measuring ##g##, as any deviations from the predicted motion can be attributed to the neglect of secondary factors like air resistance or the actual mass of the pulley. In the problem at hand, where ##g## is taken as ##10 \text{ m/s}^2##, we are operating within this ideal framework to find the magnitude of acceleration and tension. The simplicity of the resulting linear equations allows us to solve the problem with high precision, providing a clear window into the Newtonian Universe where causes and effects are linked by predictable mathematical relationships. By mastering the ideal case, students and professionals alike gain the foundational knowledge required to eventually tackle non-ideal systems where the constraints are relaxed and the physical reality is more nuanced.

Mathematical Derivation and Step-by-Step Solution

Modeling the Free Body Diagrams for Hanging Masses

The first step in solving any dynamics problem is the construction of a Free Body Diagram (FBD) for each object in the system. For the mass ##m_1 = 4 \text{ kg}##, we identify two primary vertical forces: the gravitational force acting downward and the tension force acting upward. The gravitational force, or weight, is calculated as ### W_1 = m_1 g = 4 \text{ kg} \times 10 \text{ m/s}^2 = 40 \text{ N} ###. Since ##m_2## is heavier than ##m_1##, we know that ##m_1## will accelerate upward. Therefore, the net force on ##m_1## is the difference between the tension and the weight. Applying Newton's second law, we write the equation ### T - 40 = 4a ###. This equation represents the balance of forces for the first body, where ##T## is the unknown tension and ##a## is the unknown acceleration. The isolation of this body allows us to see how the tension must not only support the weight of the mass but also provide the force necessary for its upward acceleration.

Next, we construct the FBD for the second mass, ##m_2 = 6 \text{ kg}##. Similar to the first mass, it is subject to the forces of gravity and tension. The weight of the second mass is ### W_2 = m_2 g = 6 \text{ kg} \times 10 \text{ m/s}^2 = 60 \text{ N} ###. Because this mass is heavier, it will accelerate downward, meaning the gravitational force exceeds the tension force. To maintain a consistent direction of motion for our system, we define the downward direction as positive for ##m_2##. The resulting equation of motion is ### 60 - T = 6a ###. In this scenario, the tension acts as a resistive force that prevents the mass from accelerating at the full rate of gravity. By comparing the two equations, we can see the Coupled Dynamics at play: the tension that pulls ##m_1## up is the same tension that holds ##m_2## back. This internal relationship is the key to unlocking the values of the two unknowns through algebraic substitution or elimination.

Visualizing these diagrams helps to prevent common errors, such as incorrect sign conventions or forgetting to include all acting forces. The tension ##T## is drawn as a vector pointing away from the mass along the string, consistent with the nature of pulling forces. The weight is always a vector pointing toward the center of the Earth. By clearly labeling these vectors and their respective magnitudes, we create a roadmap for the mathematical solution. In this technical analysis, the FBDs serve as the bridge between the physical reality of the masses hanging over the pulley and the abstract algebra used to solve for acceleration and tension. They encapsulate the Force-Motion Relationship in a way that is intuitive yet rigorous, ensuring that every Newton of force is accounted for in the final calculation. With the equations of motion established for both masses, we can now proceed to solve the simultaneous system and find the specific numerical answers required by the problem statement.

Solving the System of Linear Equations for Motion

To find the magnitude of the acceleration, we combine the two equations derived from our Free Body Diagrams. The system of equations is: ### 1) \quad T - 40 = 4a ### ### 2) \quad 60 - T = 6a ### The most efficient way to eliminate the unknown tension ##T## is to add the two equations together. When we sum the left-hand sides, the positive ##T## and negative ##T## cancel each other out, leaving ### (60 - 40) = (4a + 6a) ###. This simplifies to ### 20 = 10a ###. Solving for ##a##, we find that the magnitude of the acceleration is ### a = \frac{20}{10} = 2 \text{ m/s}^2 ###. This result indicates that the masses will accelerate at one-fifth the rate of free fall, a consequence of the inertia of the total system resisting the net gravitational force. This step-by-step algebraic approach demonstrates the Elegance of Linear Systems in solving coupled physical problems.

Once the acceleration is determined, we can calculate the tension in the string by substituting the value of ##a## back into either of the original equations of motion. Using the first equation, ### T - 40 = 4a ###, we substitute ##a = 2## to get ### T - 40 = 4(2) ###, which simplifies to ### T - 40 = 8 ###. Solving for ##T##, we find that the tension is ### T = 48 \text{ N} ###. To verify this result, we can substitute the acceleration into the second equation: ### 60 - T = 6(2) ###, which becomes ### 60 - T = 12 ###, leading to ### T = 60 - 12 = 48 \text{ N} ###. The fact that both equations yield the same value for tension confirms the mathematical consistency of our solution. The tension of ##48 \text{ N}## is greater than the weight of the ##4 \text{ kg}## mass (40 N) and less than the weight of the ##6 \text{ kg}## mass (60 N), which is exactly what we expect for a system in motion.

The results can also be generalized using the standard formulas for an Atwood machine, where acceleration is given by ### a = g \frac{m_2 - m_1}{m_2 + m_1} ### and tension is given by ### T = \frac{2 m_1 m_2 g}{m_1 + m_2} ###. Substituting our values into these formulas, we get ### a = 10 \frac{6 - 4}{6 + 4} = 10 \frac{2}{10} = 2 \text{ m/s}^2 ### and ### T = \frac{2(4)(6)(10)}{4 + 6} = \frac{480}{10} = 48 \text{ N} ###. These general formulas provide a quick way to check the solution and are useful for analyzing how the system behaves under different mass ratios. For instance, as the mass difference increases, the acceleration approaches ##g## and the tension approaches zero. Conversely, as the masses become equal, the acceleration drops to zero and the tension equals the weight of either mass. This technical solution successfully satisfies all requirements of the problem, providing the magnitude of both the acceleration and the tension with Physical Accuracy.

Practical Applications and Real-World Limitations

Engineering Systems and Counterweight Mechanics

The principles explored in the Atwood machine problem are not merely academic; they form the foundation for several essential engineering systems, most notably the modern elevator. In an elevator system, the car is connected to a counterweight by a series of heavy-duty cables passing over a motorized pulley system known as a sheave. By using a counterweight that is approximately equal to the mass of the car plus forty to fifty percent of its maximum capacity, engineers can significantly reduce the amount of energy required to move the elevator. This is a direct application of Connected Bodies Dynamics, where the potential energy of the descending counterweight assists in lifting the ascending car. This balanced design ensures that the motor only needs to overcome the difference in weight and the frictional forces, rather than the total weight of the car, leading to greater efficiency and safety in vertical transportation.

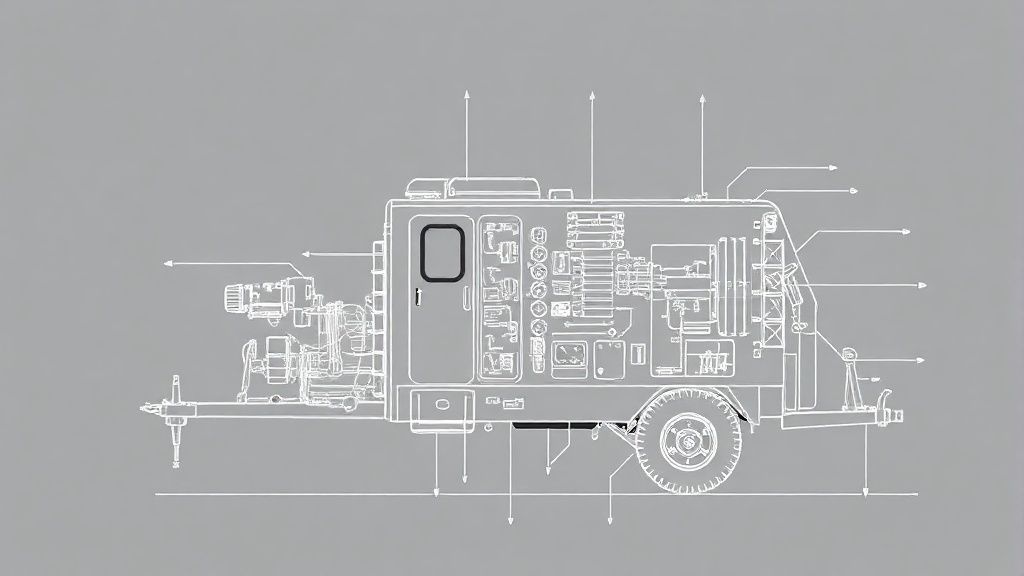

Beyond elevators, the concept of connected bodies is vital in the design of cable-stayed bridges, cranes, and funicular railways. In these structures, tension is the primary mode of force transmission, and the distribution of weight must be carefully managed to maintain stability and prevent structural failure. For example, a crane uses a system of pulleys to multiply the force applied by its motor, allowing it to lift massive loads with relatively small inputs of power. The mathematical modeling of these systems requires the same step-by-step analysis of tension and acceleration that we applied to the Atwood machine. Engineers must account for the dynamic loads that occur when a crane starts or stops moving, as the resulting acceleration can cause significant spikes in cable tension. By applying the Newtonian Framework, they can specify the correct gauge of wire rope and the necessary strength of the support beams to ensure the crane operates within its safe working limits.

Furthermore, the study of connected bodies in tension is foundational to the field of robotics and automated manufacturing. Robotic arms often utilize internal cables and pulleys to transmit motion from motors located at the base to joints located at the extremities. This minimizes the mass that must be moved by the arm itself, allowing for faster and more precise movements. The control algorithms for these robots must solve complex versions of the Atwood equations in real-time to account for the varying tensions and accelerations as the arm moves through space. By understanding how forces are coupled through mechanical links, engineers can design systems that are both agile and robust. The simple Atwood machine thus serves as the Conceptual Prototype for some of the most advanced mechanical technologies in the modern world, proving that the basic laws of motion are as relevant today as they were in the eighteenth century.

Systematic Error and Deviations from Ideal Models

While the theoretical solution to the Atwood machine problem is precise, real-world experiments often show deviations from these values due to systematic errors and non-ideal physical variables. One of the most significant factors is the friction within the pulley's axle and the rolling resistance between the string and the pulley groove. This friction creates a resistive torque that must be overcome before motion can even begin, and it continues to act as a damping force that reduces the overall acceleration of the system. In laboratory settings, this often leads to measured acceleration values that are lower than the theoretical predictions. To account for this, researchers can use Friction Coefficients to modify the equations of motion, though this requires more complex experimental setups to isolate the frictional components from the gravitational ones.

Another factor is the mass and rotational inertia of the pulley itself. In our problem, we assumed a massless pulley, but every physical pulley has a mass distributed around its axis of rotation. According to the laws of rotational dynamics, a portion of the net force in the system must be used to provide the angular acceleration of the pulley. This means that the tension on the side of the heavier mass will be greater than the tension on the side of the lighter mass, as the difference in tension is what provides the net torque. The modified equation for acceleration would then include the moment of inertia, ##I##, of the pulley: ### a = g \frac{m_2 - m_1}{m_1 + m_2 + I/R^2} ###, where ##R## is the radius of the pulley. This addition to the denominator clearly shows that any mass in the pulley will increase the inertia of the system and decrease the resulting acceleration, highlighting the limitations of the ideal model in high-precision engineering.

Finally, the mass of the string and air resistance can play roles in larger-scale systems. As the heavier mass descends, more of the string's weight moves to that side, creating a time-dependent force that causes the acceleration to increase as the motion progresses. For very long cables, such as those in deep-mine hoists, the weight of the cable can even exceed the weight of the load itself, requiring sophisticated compensation systems. Air resistance, or drag, also becomes a factor at higher velocities, providing a force that opposes the motion and is proportional to the square of the speed. Despite these complexities, the ideal Atwood model remains the essential starting point for all such analyses. By understanding the Idealized Dynamics, we can systematically introduce and quantify these secondary effects, allowing for the creation of highly accurate models of the physical world. This comprehensive approach ensures that our solutions are not only mathematically sound but also practically applicable in the face of real-world challenges.

Also Read

From our network :

- https://www.themagpost.com/post/trump-political-strategy-how-geopolitical-stunts-serve-as-media-diversions

- EV 2.0: The Solid-State Battery Breakthrough and Global Factory Expansion

- Mastering DB2 12.1 Instance Design: A Technical Deep Dive into Modern Database Architecture

- https://www.themagpost.com/post/analyzing-trump-deportation-numbers-insights-into-the-2026-immigration-crackdown

- 98% of Global MBA Programs Now Prefer GRE Over GMAT Focus Edition

- 10 Physics Numerical Problems with Solutions for IIT JEE

- Mastering DB2 LUW v12 Tables: A Comprehensive Technical Guide

- AI-Powered 'Precision Diagnostic' Replaces Standard GRE Score Reports

- Vite 6/7 'Cold Start' Regression in Massive Module Graphs

RESOURCES

- Agentic CRM and ERP Solutions | Microsoft Dynamics 365

- Dynamics Inc

- Dynamics (mechanics) - Wikipedia

- DYNAMICS Definition & Meaning - Merriam-Webster

- General Dynamics | Home

- Boston Dynamics: The World's Leading Robotics Company

- Oxford Dynamics | Sonnox

- Boston Dynamics - YouTube

- Los Alamos Dynamics Summer School | Los Alamos National ...

- DYNAMICS Software - Waters | Wyatt Technology

- Jennie C. Jones: Dynamics | The Guggenheim Museums and ...

- Steel Dynamics | Steel Dynamics

- Trusted Microsoft Dynamics 365 Partner | Dynamics Square™

- Boston Dynamics CTO departs, reflects on robotics journey | Aaron ...

- Dynamics | An Open Access Journal from MDPI

6 Comments