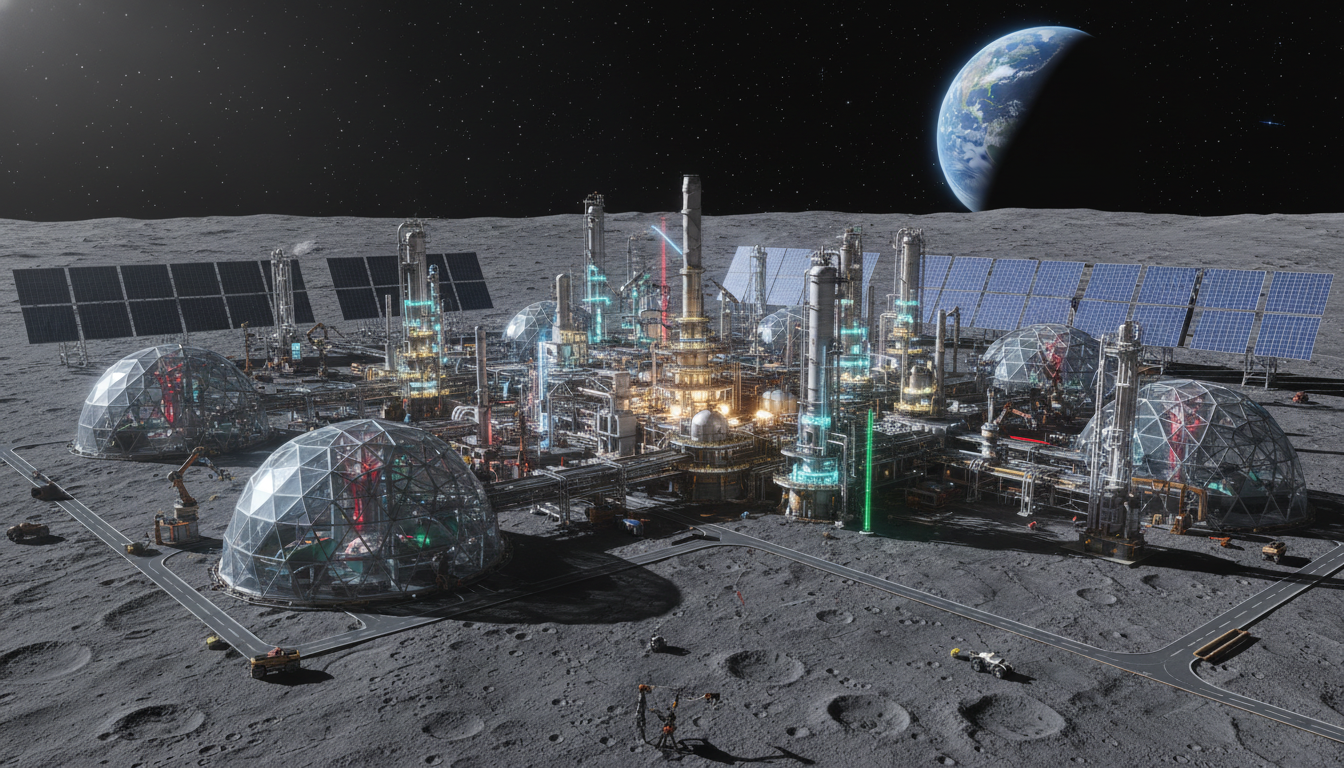

Space chemistry is revolutionizing our approach to extraterrestrial industrialization by utilizing lunar regolith for on-orbit manufacturing. By refining local materials, humanity can bypass the immense costs of launching resources from Earth. This strategic shift enables a sustainable off-world economy, focusing on chemical extraction, metal production, and vacuum-state reaction kinetics to build permanent structures and fuel systems.

- Gravity Tax Abolished: In-situ resource utilization eliminates the need for expensive Earth-to-orbit transportation of heavy raw building materials.

- Chemical Purity: Vacuum environments allow for high-purity chemical reactions and alloy mixing impossible within the Earth's dense atmosphere.

- Industrial Shift: Aerospace companies are transitioning from mere transportation providers to integrated extraterrestrial chemical manufacturers and refiners.

On This Page

- The Fundamentals of Lunar Regolith Composition

- Ilmenite Reduction Chemistry

- Average Oxide Composition

- Grain Size and Reaction Kinetics

- Thermodynamic Challenges in Vacuum

- Phase Behavior in Vacuum

- Reactor Design Considerations

- Electrolytic Extraction and Chemical Processes

- Molten Salt Electrolysis: The FFC Cambridge Process

- Illustration 5: Faraday’s Law for Mass Production

- Illustration 6: Electrical Conductivity of Molten Silicates

- Energy Considerations and Power Management

- Electrolyte Recovery and Sustainability

- Low-Gravity Fluid Dynamics and Reaction Engineering

- Economic and Strategic Implications of ISRU

The Fundamentals of Lunar Regolith Composition

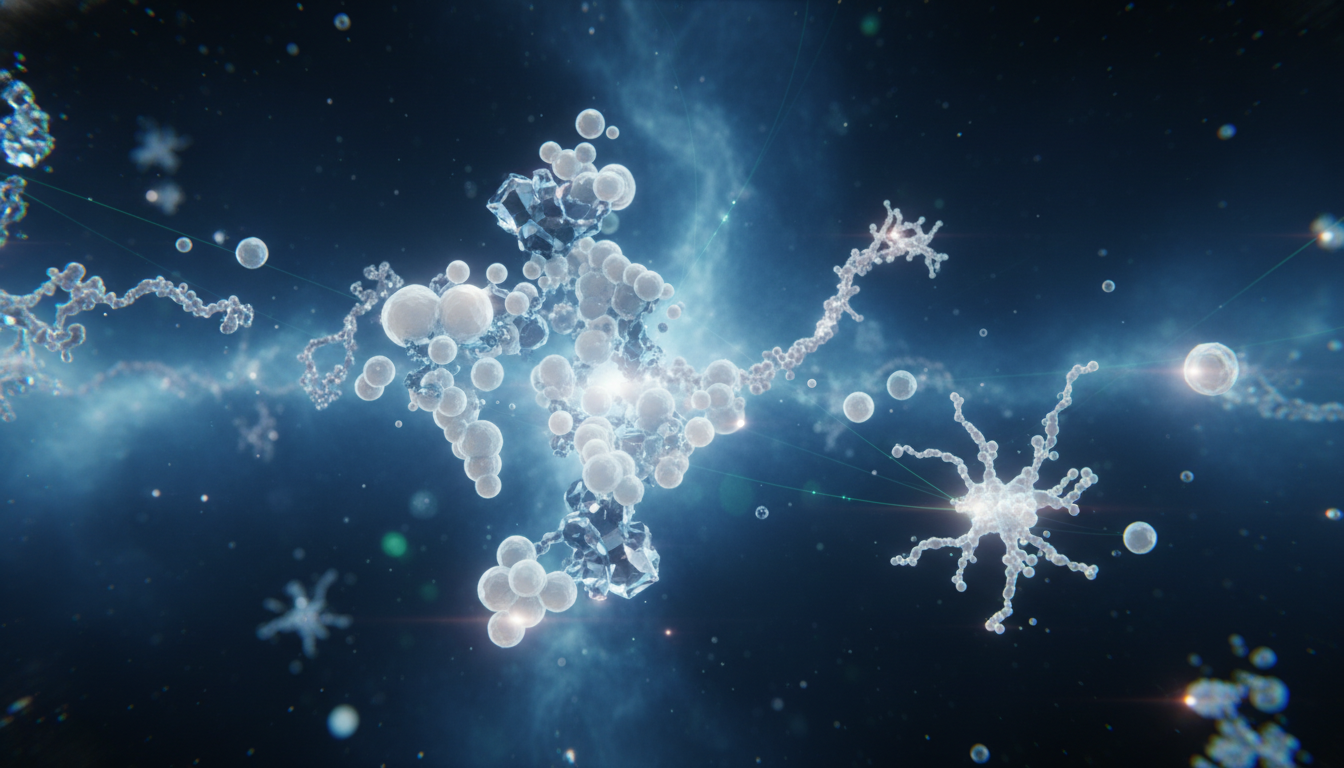

Lunar regolith is a highly fragmented layer of dust, glassy particles, and crushed rock that blankets the Moon’s surface to depths ranging from a few meters in mare regions to more than 15 meters in the highlands. Unlike terrestrial soil, it contains no organic compounds, no moisture, and no biological activity. It is a purely mineralogical material shaped by billions of years of micrometeorite impacts and solar wind exposure.

Its composition includes oxygen (bound in oxides), silicon, aluminum, iron, calcium, magnesium, and titanium. These elements form the backbone of structural metals, ceramics, glass, and life-support systems. Understanding their distribution is the first requirement for in-situ resource utilization (ISRU).

Mineralogical Structure of Regolith

The absence of atmosphere and water means weathering on the Moon is mechanical rather than chemical. Repeated impact events produce angular grains with extremely high surface reactivity. The material is primarily composed of silicate minerals such as pyroxene, olivine, plagioclase feldspar, and ilmenite.

These silicates are thermodynamically stable compounds that require substantial energy input for reduction. Their oxide bonds are strong, meaning extraction processes must overcome large Gibbs free energy barriers.

| Mineral | Formula | Key Elements | Industrial Value |

|---|---|---|---|

| Ilmenite | FeTiO₃ | Fe, Ti, O | Oxygen extraction, titanium production |

| Pyroxene | (Mg,Fe)SiO₃ | Mg, Fe, Si | Magnesium alloys |

| Plagioclase | CaAl₂Si₂O₈ | Ca, Al, Si | Aluminum extraction |

| Olivine | (Mg,Fe)₂SiO₄ | Mg, Fe | Metal recovery |

Ilmenite Reduction Chemistry

Hydrogen reduction of ilmenite is one of the most studied oxygen extraction pathways:

### FeTiO_3 + H_2 \xrightarrow{\Delta} Fe + TiO_2 + H_2O ###

Stoichiometric calculation:

Molar mass of FeTiO₃ ≈ 151.7 g/mol Oxygen content = 48 g per mole

### \frac{48}{151.7} \approx 0.316 ###

Theoretical oxygen content in 1 kg:

### 1000 \times 0.316 = 316\ g ###

Practical extraction efficiencies (~30–35%) yield roughly 100–110 grams of usable oxygen per kilogram of ilmenite.

Average Oxide Composition

### SiO_2: 45\%, \quad Al_2O_3: 15\%, \quad CaO: 12\%, \quad FeO: 10\%, \quad MgO: 9\% ###

| Oxide | Mass % | Reduction Energy Demand |

|---|---|---|

| SiO₂ | 45% | Very High |

| Al₂O₃ | 15% | Extremely High |

| CaO | 12% | Moderate |

| FeO | 10% | Lower (hydrogen reducible) |

| MgO | 9% | High |

Grain Size and Reaction Kinetics

Reaction rate depends strongly on available surface area. If particle diameter decreases, surface area per unit mass increases.

For spherical grains:

### A = \frac{6}{\rho d} ###

Smaller grain diameter ##d## increases reactive surface area ##A##, accelerating oxygen extraction.

Thermodynamic Challenges in Vacuum

Without atmosphere, heat rejection relies entirely on radiation:

### P = \epsilon \sigma A (T^4 - T_{space}^4) ###

Where:

- ##\epsilon## — emissivity

- ##\sigma = 5.67 \times 10^{-8} W/m^2K^4##

- ##T_{space} \approx 3K##

Convective cooling is impossible. Reactor walls must dissipate kilowatts of thermal energy via radiators.

Example Radiative Cooling Calculation

If:

- ##\epsilon = 0.9##

- ##A = 10\ m^2##

- ##T = 1200\ K##

### P \approx 0.9 \times 5.67\times10^{-8} \times 10 \times (1200^4) ###

### \approx 0.9 \times 5.67\times10^{-8} \times 10 \times 2.07\times10^{12} ###

### \approx 1055\ kW ###

This demonstrates the enormous thermal loads involved in lunar refining.

Phase Behavior in Vacuum

Low pressure alters phase diagrams. Materials may sublime directly:

### \Delta G = \Delta H - T\Delta S ###

If entropy gain is high enough at low pressure, solid → gas transition becomes favorable.

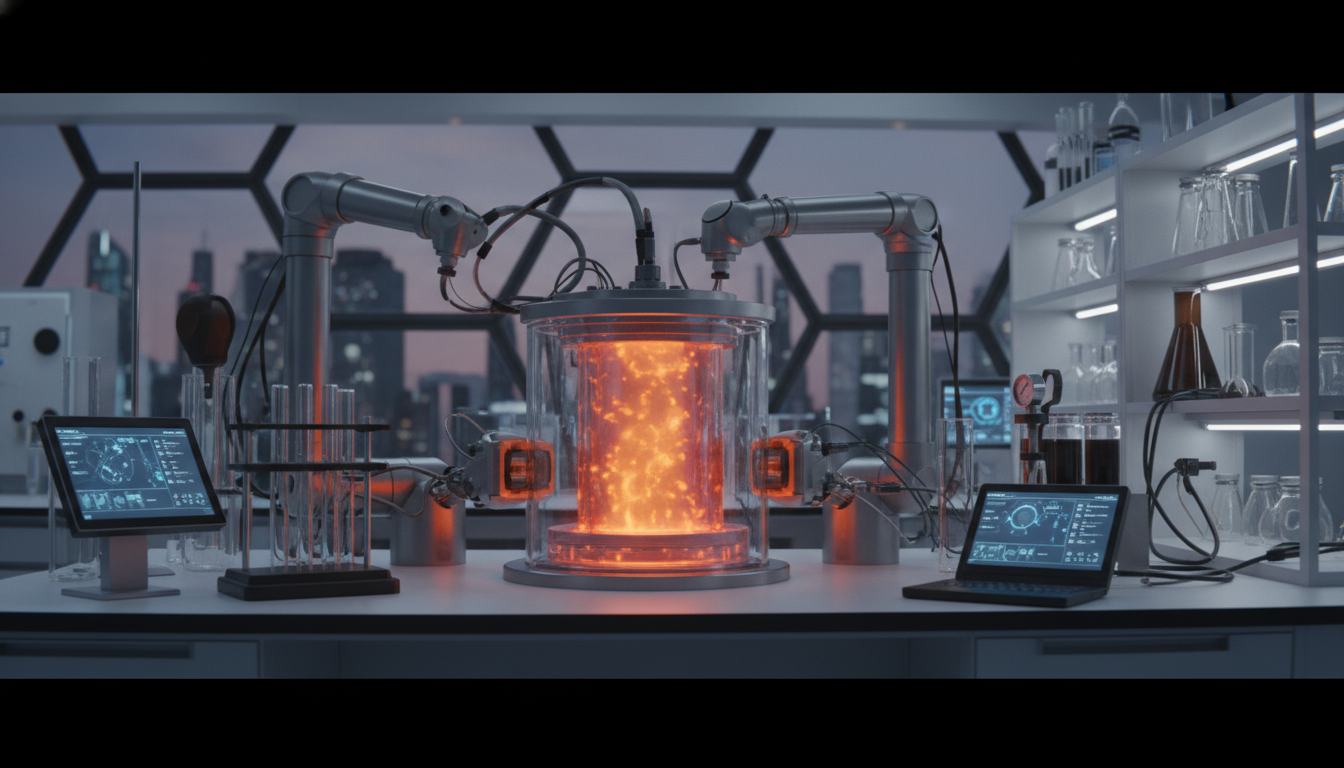

Reactor Design Considerations

- Pressurized chambers required for gas-solid reactions.

- Thermal insulation must prevent catastrophic heat loss.

- Vacuum-compatible seals are critical.

- Material fatigue from thermal cycling must be addressed.

Lunar regolith refining is fundamentally a problem of high-temperature oxide chemistry under vacuum constraints. Mastery of thermodynamics, reaction kinetics, and radiative heat transfer will define the success of extraterrestrial chemical engineering.

Electrolytic Extraction and Chemical Processes

Electrolysis is one of the most promising pathways for extracting oxygen and metals from lunar regolith. Unlike spontaneous chemical reductions, electrolysis uses external electrical energy to drive thermodynamically uphill reactions. In the lunar environment, where sunlight is abundant during the day, solar-powered electrochemical systems offer a scalable refining strategy.

Molten salt electrolysis is particularly attractive because lunar oxides are stable at room temperature but become electrochemically reducible when dissolved or suspended in high-temperature molten salts.

Principle of Molten Salt Electrolysis

In molten salt systems, lunar oxide materials are immersed in a liquid electrolyte (commonly CaCl₂) at temperatures above 900–1000°C. The molten salt conducts oxygen ions efficiently.

- Cathode: Reduction of metal oxide

- Anode: Oxidation and oxygen evolution

Pure metal deposits at the cathode while oxygen gas evolves at the anode.

Molten Salt Electrolysis: The FFC Cambridge Process

The FFC Cambridge process is one of the leading candidates for lunar refining because it directly reduces solid oxides into metallic form without requiring complete melting of the oxide itself.

### MO_x + 2xe^- \rightarrow M + xO^{2-} ###

Here:

- ##MO_x## = metal oxide (e.g., FeO, TiO₂, Al₂O₃)

- ##M## = reduced metal

- ##O^{2-}## migrates through the molten salt toward the anode

At the anode, oxygen ions combine to form molecular oxygen:

### 2O^{2-} \rightarrow O_2 + 4e^- ###

This oxygen can be captured for life support or propellant production.

| Component | Role | Design Requirement |

|---|---|---|

| Molten CaCl₂ | Electrolyte medium | High oxygen ion conductivity |

| Cathode | Metal formation site | High electrical conductivity |

| Anode | Oxygen evolution | Corrosion resistance |

| Power Supply | Drives reduction | Continuous energy input |

Illustration 5: Faraday’s Law for Mass Production

### m = \frac{Q \cdot M}{n \cdot F} ###

Where:

- ##m## = mass of metal produced

- ##Q## = total electrical charge passed

- ##M## = molar mass

- ##n## = number of electrons transferred

- ##F = 96485 \text{ C/mol}##

Example Calculation

Suppose we reduce FeO (Fe²⁺ requires 2 electrons):

- ##M_{Fe} = 55.85 g/mol##

- ##n = 2##

- ##Q = 1 \times 10^6 C##

### m = \frac{(1\times10^6)(55.85)}{2 \times 96485} ###

### \approx \frac{55.85\times10^6}{192970} ###

### \approx 289 g ###

Thus, passing one million coulombs produces roughly 0.29 kg of iron.

Illustration 6: Electrical Conductivity of Molten Silicates

### \kappa = A \exp\left(-\frac{E_a}{RT}\right) ###

This Arrhenius-type equation shows conductivity increases exponentially with temperature.

- Higher ##T## → increased ion mobility

- Lower ##E_a## → easier oxygen ion transport

| Parameter | Effect on Efficiency | Engineering Strategy |

|---|---|---|

| Temperature | Higher conductivity | Thermal insulation + radiators |

| Electrode Material | Lower resistance | Graphite / Cermet testing |

| Salt Purity | Reduced parasitic reactions | Closed-loop purification |

| Voltage Control | Minimized energy loss | Optimized power electronics |

Energy Considerations and Power Management

Lunar electrolysis requires continuous power. Solar panels provide energy during the 14-day lunar day, but energy storage systems (batteries or regenerative fuel cells) are necessary during the 14-day lunar night.

Energy efficiency is determined by:

### \eta = \frac{\text{Theoretical Minimum Energy}}{\text{Actual Energy Input}} ###

Reducing ohmic losses and overpotential at electrodes is critical to maintaining high efficiency.

Electrolyte Recovery and Sustainability

In space operations, material loss is unacceptable. Calcium chloride must be continuously recycled. Oxygen release must not contaminate the electrolyte bath. Closed-loop salt purification systems will be essential.

Energy management defines industrial viability on the Moon.

Electrolysis converts regolith oxides into usable metals and oxygen.

Faraday’s law governs production scaling.

Conductivity improves exponentially with temperature.

Salt recovery ensures long-term sustainability.

We Also Published

Gas-Solid Reaction Kinetics

Hydrogen reduction is another viable method for oxygen extraction. It involves passing hydrogen gas over heated lunar regolith.

The hydrogen reacts with iron oxides to produce water. This water is then electrolyzed to recover hydrogen.

Illustration 7: Arrhenius Equation for Reaction Rates

$$k = A e^{-E_a / (RT)}$$

Determining the rate constant \(k\) is vital for reactor sizing.The reaction rate depends on the gas flow velocity. High velocities can cause fluidization of the regolith particles.

Fluidized bed reactors offer excellent mass and heat transfer. However, they are difficult to manage in low gravity.

Illustration 8: Gas Diffusion in Porous Regolith

$$J = -D_{eff} \frac{dc}{dx}$$

Effective diffusivity \(D_{eff}\) accounts for the porosity of the soil bed.We must optimize the residence time of the gas. This ensures maximum conversion of the oxides within the reactor.

Scrubbing the product stream removes impurities before electrolysis. This protects the electrochemical cells from contamination and damage.

Low-Gravity Fluid Dynamics and Reaction Engineering

Fluid behavior changes significantly in the Moon's 1/6th gravity. Surface tension becomes a dominant force in liquid management.

Buoyancy-driven convection is greatly reduced compared to Earth. This affects how heat and mass move through fluids.

Chemical reactors must be redesigned to handle these changes. Mixing becomes more difficult without the help of gravity.

Gas bubbles do not rise as quickly in liquids. This can lead to gas buildup and reduced reaction efficiency.

Engineers use centrifugal forces to simulate gravity in reactors. Rotating drums can help separate phases and improve mixing.

Mass Transfer in Microgravity

Mass transfer is limited by diffusion in low-gravity environments. We cannot rely on natural convection to stir the reactants.

Mechanical agitation is necessary to maintain uniform concentrations. This adds complexity and weight to the processing equipment.

Illustration 9: Sherwood Number for Mass Transfer

$$Sh = \frac{kL}{D}$$

In low gravity, \(Sh\) approaches the diffusive limit for stagnant fluids.Surface tension gradients can cause Marangoni convection in liquids. This provides some mixing but is often unpredictable.

Controlling the interface between gas and liquid is challenging. Capillary action can pull liquids into unwanted areas.

Illustration 10: Bond Number Calculation

$$Bo = \frac{\Delta \rho g L^2}{\sigma}$$

Low \(Bo\) indicates that surface tension dominates over gravitational forces.Illustration 11: Navier-Stokes in Low Gravity

$$\rho \left( \frac{\partial \mathbf{v}}{\partial t} + \mathbf{v} \cdot \nabla \mathbf{v} \right) = -\nabla p + \mu \nabla^2 \mathbf{v} + \rho \mathbf{g}_{lunar}$$

The gravity term \(\mathbf{g}_{lunar}\) is only 1.62 m/s².Predicting fluid flow requires advanced computational fluid dynamics. Models must account for the unique constraints of space.

Heat Management in Space Reactors

Thermal gradients can cause structural stress in reactor walls. Uniform heating is difficult to achieve without convection.

Induction heating is a precise way to melt regolith. It targets the material directly without heating the entire vessel.

Illustration 12: Heat Conduction in Regolith Bed

$$q = -k_{reg} \nabla T$$

Thermal conductivity \(k_{reg}\) is very low in a vacuum environment.Multi-layer insulation is used to prevent heat loss. This keeps the reactor at the required high temperatures.

Waste heat must be rejected into space efficiently. Large radiator panels are a common feature of space refineries.

Illustration 13: View Factor for Radiative Transfer

$$Q_{1 \rightarrow 2} = A_1 F_{12} \sigma (T_1^4 - T_2^4)$$

The view factor \(F_{12}\) determines how much radiation reaches the radiator.Thermal cycling during the lunar day and night is harsh. Materials must resist fatigue from repeated heating and cooling.

Active cooling loops may be required for sensitive electronics. These loops use specialized coolants with low freezing points.

Economic and Strategic Implications of ISRU

The "Gravity Tax" refers to the cost of escaping Earth's pull. It currently limits the scale of space activities.

By refining materials on the moon, we eliminate this tax. This makes large-scale construction in orbit economically feasible.

A lunar refinery can produce structural beams and solar panels. These items are too heavy to launch from Earth.

The shift from "transporting" to "manufacturing" is a major milestone. It signals the beginning of a true space economy.

Strategic control of lunar resources will define future geopolitics. The moon is the high ground of the solar system.

The Abolition of the Gravity Tax

Launching 1 kg of material to the moon is expensive. Refining 1 kg on the moon is much cheaper.

The delta-v required to reach orbit from the moon is small. This makes lunar products competitive for orbital use.

Illustration 14: Delta-V Savings Comparison

$$V_{Earth \rightarrow LEO} \approx 9.4 \text{ km/s}, \quad V_{Moon \rightarrow LEO} \approx 2.4 \text{ km/s}$$

Energy required is proportional to the square of Delta-V.Space-based manufacturing allows for much larger structures. We are no longer limited by the size of rocket fairings.

This enables the construction of massive space stations and ships. These vessels can be built entirely in orbit.

Resource independence is the key to long-term survival. We must learn to "live off the land" in space.

Investors are increasingly looking at lunar mining startups. The potential returns from a lunar economy are astronomical.

Future of Extraterrestrial Chemical Engineering

A new niche for "Extraterrestrial Chemical Engineering" is emerging. This field focuses on reactions in non-Earth environments.

Specialized space-hardened reactors are currently being developed. These machines must be autonomous and highly reliable.

Illustration 15: Mass Balance for Oxygen Production Plant

$$\dot{m}_{regolith} = \dot{m}_{metal} + \dot{m}_{oxygen} + \dot{m}_{slag}$$

Total mass flow must be balanced for continuous operation.Students should specialize in vacuum-state reaction kinetics. This knowledge will be in high demand very soon.

Robotic systems will perform most of the refining work. Artificial intelligence will manage the complex chemical processes.

The first lunar refineries will be small pilot plants. They will prove the technology before scaling to industrial levels.

Success in lunar refining will pave the way for Mars. The same principles apply to the Martian regolith.

Also Read

From our network :

- 98% of Global MBA Programs Now Prefer GRE Over GMAT Focus Edition

- https://www.themagpost.com/post/trump-political-strategy-how-geopolitical-stunts-serve-as-media-diversions

- Mastering DB2 12.1 Instance Design: A Technical Deep Dive into Modern Database Architecture

- AI-Powered 'Precision Diagnostic' Replaces Standard GRE Score Reports

- Vite 6/7 'Cold Start' Regression in Massive Module Graphs

- https://www.themagpost.com/post/analyzing-trump-deportation-numbers-insights-into-the-2026-immigration-crackdown

- Mastering DB2 LUW v12 Tables: A Comprehensive Technical Guide

- EV 2.0: The Solid-State Battery Breakthrough and Global Factory Expansion

- 10 Physics Numerical Problems with Solutions for IIT JEE

RESOURCES

- Production of Steel from Lunar Regolith through Carbonyl Iron ...

- Materials Refining for Solar Array Production on the Moon

- The first step to a near term orbiting habitat in Mars orbit is refining ...

- Materials refining on the Moon - ScienceDirect.com

- Production of Steel from Lunar Regolith through Carbonyl Iron ...

- Materials refining on the Moon - Open Source Ecology wiki

- FINAL PROJECT REPORT - NASA's BIG Idea Challenge

- Materials refining on the Moon - NASA ADS

- Materials Refining for Structural Elements From Lunar Resources

- Refining a Thermophysical Model of the Lunar Surface using Eclipses

- Lunar Resources

- Refining lunar impact chronology through high spatial resolution 40 Ar

- Enhancing Additive Manufacturing of Lunar Regolith Ceramics ...

- Additive Manufacturing of Functionally Graded Materials from Lunar ...

- Refining Lunar Regolith - YouTube

0 Comments