On This Page

We'll explore a remarkable achievement in Russian Jet Engine Production. For decades, creating turbine blades—the heart of jet engines—was a painstaking process, taking months of meticulous machining. However, a new method using powder metallurgy and additive manufacturing has dramatically changed this. This innovative approach, now fully implemented in Russia, has slashed production time, leading to a tenfold increase in efficiency. Consequently, Russian Jet Engine Production has gained a significant competitive edge globally.

Furthermore, this isn't just about speed. This revolutionary technique allows for incredibly intricate blade designs, previously impossible to manufacture. These enhanced designs lead to better engine performance, increased fuel efficiency, and improved reliability. In short, the advancements in Russian Jet Engine Production represent a major leap forward, impacting both military and civilian aviation. The implications are far-reaching, promising a new generation of superior aircraft.

We also Published

The Dawn of a New Era in Turbine Blade Manufacturing

The realm of aerospace engineering has witnessed a momentous stride forward with the advent of a revolutionary technique in gas turbine engine production. For decades, the fabrication of turbine blades, those critical components enduring immense heat and rotational speeds within a jet engine, has relied upon the laborious method of machining solid metal blocks. This time-consuming process, often spanning several months, presented a significant bottleneck in engine production. However, a groundbreaking shift has occurred, spearheaded by advancements in powder metallurgy. This innovative approach, now implemented in Russia, has drastically curtailed production time, transforming the landscape of jet engine manufacturing. The implications of this technological leap extend far beyond mere efficiency gains; it represents a strategic advantage in the global aerospace industry, signifying a nation's prowess in high-precision manufacturing and materials science. The new method, utilizing additive manufacturing, promises not only faster production but also the potential for enhanced blade designs and improved engine performance. This advancement underscores the importance of continuous innovation in propelling technological frontiers and securing national competitiveness in strategically vital sectors.

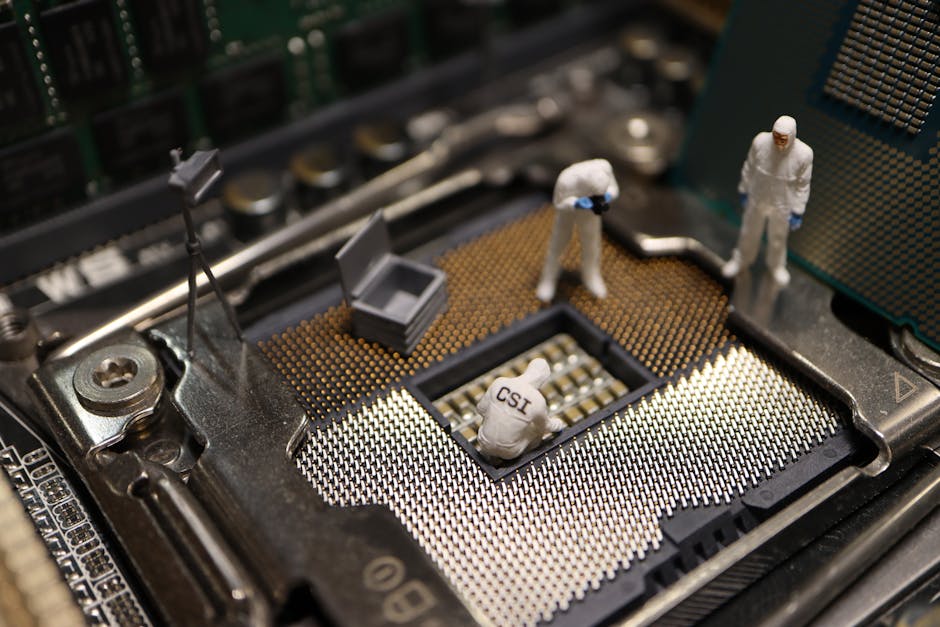

The transition from traditional subtractive manufacturing to additive manufacturing marks a paradigm shift in the production of turbine blades. The meticulous process of carving blades from solid metal ingots, a method fraught with material waste and extended lead times, is now superseded by the precise layering of microscopic metal powder particles. This additive approach, often referred to as 3D printing on an industrial scale, offers unparalleled control over the final product's geometry and microstructure. The ability to create intricate internal cooling channels within the blades, for instance, significantly enhances their thermal resistance and allows for higher operating temperatures. This translates directly to improved engine efficiency and thrust, providing a competitive edge in the design and performance of modern jet engines. The implications for both military and commercial aviation are profound, promising a new generation of more powerful, fuel-efficient, and reliable aircraft.

Additive Manufacturing: A Paradigm Shift in Precision Engineering

The core of this revolutionary advancement lies in the application of additive manufacturing, a process that fundamentally alters the approach to creating complex components. Unlike traditional subtractive methods that begin with a large block of material and remove excess to achieve the desired shape, additive manufacturing builds the component layer by layer from a powdered metal precursor. This technique allows for the creation of intricate geometries and internal structures that would be impossible to achieve through conventional machining. In the context of turbine blades, this means the incorporation of complex cooling channels and optimized airfoil designs, leading to significant improvements in performance and durability. The precision and control afforded by additive manufacturing also minimize material waste, contributing to both economic and environmental benefits. This method's adaptability to various materials further expands its potential applications across diverse engineering disciplines, promising a future where complex components are produced with unprecedented speed and accuracy.

The transition to additive manufacturing in turbine blade production represents more than just a technological upgrade; it signifies a fundamental shift in the manufacturing paradigm. The ability to create complex, high-performance components with significantly reduced lead times has profound implications for the aerospace industry and beyond. This approach not only accelerates production but also opens up new avenues for design optimization, allowing engineers to explore previously unattainable geometries and material combinations. The precision and control offered by additive manufacturing translate to improved component reliability and durability, leading to enhanced safety and reduced maintenance costs. Furthermore, the reduced material waste inherent in this process contributes to a more sustainable manufacturing practice, aligning with growing global concerns about environmental responsibility. The implications of this technological leap extend far beyond the aerospace sector, promising to revolutionize manufacturing across a wide range of industries.

Strategic Implications: Securing a Nation's Aerospace Prowess

The mastery of advanced manufacturing techniques, such as the additive manufacturing of turbine blades, holds significant strategic implications for a nation's standing in the global aerospace industry. The ability to produce complete jet engines domestically, rather than relying on foreign suppliers, ensures national security and reduces dependence on external sources. This self-sufficiency is particularly crucial for military applications, where the reliability and availability of advanced propulsion systems are paramount. Moreover, the development and implementation of cutting-edge manufacturing technologies fosters innovation and strengthens a nation's technological capabilities, attracting skilled engineers and researchers and boosting economic growth. The advancements in powder metallurgy and additive manufacturing showcased in this context are not merely technological achievements; they represent a strategic investment in national competitiveness and security.

Beyond the immediate benefits of reduced production time and enhanced component performance, the mastery of advanced manufacturing techniques like additive manufacturing for turbine blades has profound geopolitical implications. Control over the entire jet engine production chain, from materials science to final assembly, translates to a significant strategic advantage in the global aerospace arena. This self-reliance reduces vulnerability to supply chain disruptions and geopolitical instability, ensuring the continued availability of critical technologies for both military and civilian applications. Furthermore, the development and deployment of such advanced manufacturing capabilities fosters a skilled workforce, attracting investment and driving economic growth within the nation. The technological prowess demonstrated in this achievement serves as a testament to the importance of investing in research and development and cultivating a culture of innovation.

The Future of Jet Engine Technology: A Glimpse into Tomorrow

The successful implementation of additive manufacturing in turbine blade production heralds a new era in jet engine technology, promising further advancements in engine performance, efficiency, and reliability. Ongoing research into new materials and manufacturing processes will continue to push the boundaries of what is possible, leading to lighter, more powerful, and environmentally friendly engines. The integration of artificial intelligence and machine learning into the design and manufacturing processes will further optimize engine performance and reduce production costs. The future of jet engine technology is bright, driven by innovation and a relentless pursuit of excellence in engineering and manufacturing.

Looking ahead, the future of jet engine technology promises even more dramatic advancements fueled by the continued refinement of additive manufacturing techniques. The exploration of novel materials, such as advanced ceramics and composites, will further enhance the performance and durability of turbine blades, enabling higher operating temperatures and increased engine efficiency. The integration of sophisticated sensors and data analytics will allow for real-time monitoring of engine health and predictive maintenance, minimizing downtime and maximizing operational reliability. Furthermore, the development of hybrid-electric propulsion systems, coupled with advancements in battery technology, will pave the way for more sustainable and environmentally friendly aircraft. The convergence of these technological advancements promises a future where air travel is both more efficient and more environmentally responsible.

0 Comments