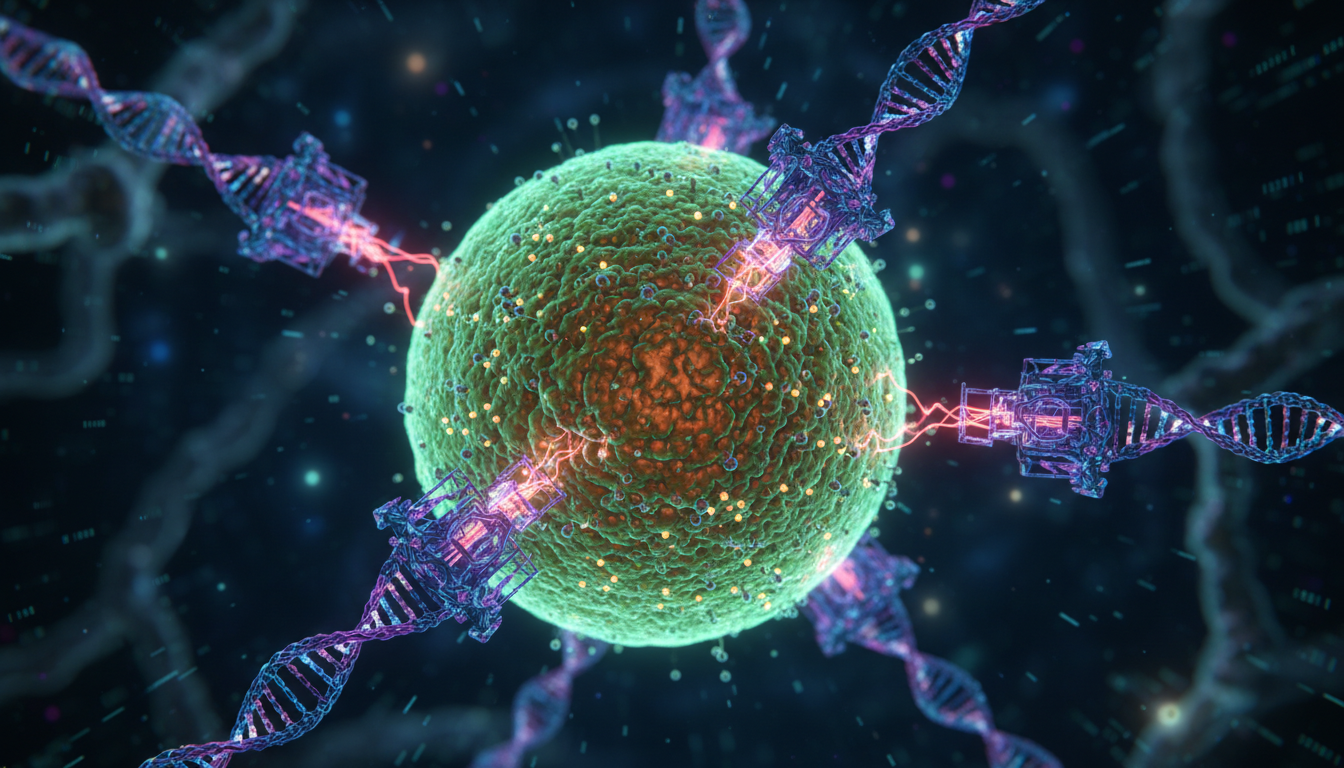

- Atmospheric CO2 is harvested as a sustainable carbon mine.

- Advanced copper catalysts enable the conversion of CO2 to ethylene.

- Policy incentives for atmospheric carbon content are crucial for market scaling.

On This Page

The Fundamentals of Direct Air Capture (DAC) for Polymer Synthesis

Thermodynamics of CO2 Capture

Direct air capture (DAC) technologies are essential for mitigating atmospheric carbon dioxide levels. These systems utilize chemical reactions to pull CO2 directly from ambient air, regardless of the emission source or location.

The thermodynamic feasibility of DAC is determined by the energy required to reverse the entropy of mixing. Because CO2 is dilute in the atmosphere, the work required is substantially higher than flue-gas capture.

Engineers utilize the Gibbs free energy equation to calculate the theoretical minimum energy for separation. This baseline helps in evaluating the efficiency of various sorbents and solvents used in the capture process.

Solid sorbents, such as amine-functionalized resins, offer a promising pathway for lower-energy regeneration. These materials bind CO2 at ambient temperatures and release it when subjected to moderate heat or shifts in partial pressure.

Liquid solvents like potassium hydroxide are also common in industrial-scale DAC operations. These systems produce aqueous carbonates which are subsequently processed through a pellet reactor and a high-temperature calciner to recover gas.

The integration of renewable energy sources is critical for ensuring the DAC process remains carbon-negative. Without a clean energy grid, the carbon footprint of the capture machinery might exceed the carbon sequestered.

Problem 1: Calculating the Theoretical Minimum Energy for CO2 Separation

To determine the minimum isothermal work ##[W_{min}]## required to separate CO2 from air, we use the following thermodynamic relationship based on the change in Gibbs free energy:

###[W_{min} = RT \left[ \ln\left(\frac{1}{y_{CO_2}}\right) + \frac{1-y_{CO_2}}{y_{CO_2}} \ln\left(\frac{1}{1-y_{CO_2}}\right) \right]]###Where ##[R]## is the gas constant (8.314 J/mol·K), ##[T]## is the absolute temperature (298 K), and ##[y_{CO_2}]## is the mole fraction of CO2 in air (approx. 0.000415). Solving this yields approximately 20 kJ/mol.

Energy Balances in Sorbent Regeneration

The regeneration step is the most energy-intensive part of the Direct Air Capture cycle. It requires overcoming the strong chemical bonds formed between the CO2 molecules and the sorbent material during capture.

Heat of adsorption varies significantly between physical and chemical sorbents, impacting the overall thermal load. Chemical sorbents generally require higher temperatures to break the carbamate or carbonate bonds formed during the process.

Energy balances must account for the sensible heat required to raise the temperature of the entire sorbent bed. This includes the support structure and any residual moisture that may be present within the material.

Vacuum pressure swing adsorption (VPSA) can sometimes reduce the thermal requirement by lowering the partial pressure of CO2. This allows for regeneration at lower temperatures, potentially utilizing waste heat from industrial processes.

Efficiency is often measured by the Second Law efficiency, comparing actual energy use to the theoretical minimum. Most current DAC pilot plants operate at efficiencies between five and ten percent of the limit.

Optimizing the cycle time is another critical factor in maintaining a positive energy balance. Faster cycles increase the throughput of the facility but may lead to higher mechanical wear and energy losses.

Catalytic Conversion of Atmospheric CO2 to Ethylene

Copper-Based Electrocatalysis Mechanisms

The conversion of captured CO2 into ethylene is a cornerstone of the emerging atmochemical industry. Copper is uniquely capable of catalyzing the multi-electron reduction of CO2 into multi-carbon products like ethylene and ethanol.

The mechanism involves the adsorption of CO molecules onto the copper surface, followed by C-C coupling. This coupling step is the rate-limiting transition that determines the selectivity toward ethylene over methane.

Nanostructuring the copper surface can significantly enhance the local concentration of intermediate species. By creating specific facets or grain boundaries, researchers can steer the reaction toward the desired high-value olefin products.

Electrolyte composition also plays a vital role in managing the local pH at the catalyst-liquid interface. Maintaining a high local alkalinity suppresses the hydrogen evolution reaction, which otherwise competes for electrons.

Gas diffusion electrodes (GDEs) are employed to overcome the low solubility of CO2 in aqueous environments. These electrodes allow for a direct interface between the gaseous feedstock and the solid catalyst surface.

Ongoing research into tandem catalysts seeks to combine CO2-to-CO and CO-to-ethylene steps into a single reactor. This approach could simplify the manufacturing pipeline and reduce the overall capital expenditure for chemical plants.

Problem 2: Faraday's Law for Ethylene Production Rate

In an electrochemical cell, the mass of ethylene produced is proportional to the total charge passed. The relationship is defined by Faraday's Law of electrolysis for a multi-electron process:

###[m = \frac{Q \cdot M}{z \cdot F} \cdot \eta_{FE}]###Where ##[m]## is the mass of ethylene, ##[Q]## is the total charge in Coulombs, ##[M]## is the molar mass of ethylene (28.05 g/mol), ##[z]## is the number of electrons (12 for CO2 to C2H4), ##[F]## is Faraday's constant (96,485 C/mol), and ##[\eta_{FE}]## is the Faradaic efficiency.

Stoichiometry of the Sabatier and Fischer-Tropsch Variations

While electrocatalysis is gaining traction, thermochemical routes like the Sabatier reaction remain highly relevant. These processes involve reacting CO2 with green hydrogen over metal catalysts to produce methane or methanol.

Methanol can then be converted into ethylene via the Methanol-to-Olefins (MTO) process. This established industrial pathway provides a reliable bridge between atmospheric carbon and the existing polymer supply chain infrastructure.

The Fischer-Tropsch synthesis offers another alternative for producing long-chain hydrocarbons from CO2 and hydrogen. By adjusting the catalyst and reaction conditions, the distribution of products can be shifted toward specific monomers.

Stoichiometric control is essential for maximizing the yield of target molecules while minimizing side products. The ratio of hydrogen to carbon dioxide must be carefully balanced to maintain the desired oxidation state.

Heat management is a significant challenge in thermochemical conversion due to the exothermic nature of these reactions. Advanced reactor designs use microchannel cooling to maintain precise temperature control across the catalyst bed.

The integration of DAC with these thermochemical processes creates a closed-loop system for carbon utilization. This synergy transforms the atmosphere into a dynamic carbon mine, decoupling plastic production from fossil fuel extraction.

Recommended Reads

From Feedstock to Polymer: The Manufacturing Pipeline

Polymerization Kinetics of Sky-Polyethylene

Once ethylene is produced from atmospheric CO2, it undergoes polymerization to form polyethylene. The kinetics of this reaction are identical to those using fossil-derived ethylene, ensuring drop-in compatibility for manufacturers.

Ziegler-Natta or metallocene catalysts are typically used to control the molecular weight distribution of the polymer. These catalysts allow for the production of high-density or linear low-density polyethylene with specific properties.

The purity of the atmospheric ethylene feedstock is paramount for maintaining catalyst activity. Trace contaminants from the DAC or conversion steps must be removed to prevent poisoning of the polymerization catalysts.

Reaction temperature and pressure are the primary variables used to tune the polymer's branching and density. High-pressure processes produce low-density polyethylene (LDPE), while lower pressures favor higher-density variants (HDPE) for structural use.

Batch versus continuous polymerization strategies depend on the scale of the DAC-integrated facility. Continuous processes offer better consistency and energy efficiency for large-volume production of standard plastic grades used globally.

The resulting "Sky-Polyethylene" is chemically indistinguishable from its petrochemical counterpart at the molecular level. This allows it to be used in existing injection molding and extrusion machinery without any modifications.

Code Block 1: Simulating Carbon Sequestration in Polymer Production

def calculate_net_carbon(mass_plastic_kg, energy_intensity_kwh_per_kg, carbon_intensity_grid):

# Carbon content in Polyethylene (C2H4)n is approx 85.7%

sequestered_co2 = mass_plastic_kg * (44.01 / 28.05) * 2 # Stoichiometric CO2 equivalent

emitted_co2 = mass_plastic_kg * energy_intensity_kwh_per_kg * carbon_intensity_grid

net_impact = sequestered_co2 - emitted_co2

return net_impact

# Example: 1000kg plastic, 5kWh/kg energy, 0.1kgCO2/kWh grid

print(f"Net CO2 Sequestered: {calculate_net_carbon(1000, 5, 0.1)} kg")Material Properties and Durability Comparison

The performance of atmospheric-derived plastics is a critical factor for their adoption in durable goods. Testing shows that Sky-Polyethylene meets or exceeds all standard mechanical specifications for tensile strength and impact resistance.

Durability is particularly important when these materials are used in long-lived applications like car parts or building materials. In these roles, the plastic serves as a permanent reservoir for atmospheric carbon.

Thermal stability and UV resistance are also evaluated to ensure the material can withstand environmental exposure. Additives used in traditional plastics are equally effective in stabilizing atmospheric-derived polymers for outdoor use.

The recyclability of Sky-Polyethylene is identical to conventional plastics, supporting a circular economy. Mechanical and chemical recycling methods can be used to extend the life of the sequestered carbon further.

Life-cycle studies indicate that using these plastics in construction can sequester carbon for decades or centuries. This long-term storage is a key advantage over short-lived products like packaging or single-use items.

As the technology matures, we expect to see a wider range of polymers produced from air. This includes polycarbonates and polyurethanes, which offer even higher carbon density and broader industrial applications.

Economic and Environmental Impact of Atmochemical Industries

Life Cycle Assessment (LCA) and Carbon Sequestration

A comprehensive Life Cycle Assessment (LCA) is necessary to validate the carbon-negative claims of DAC-to-plastic processes. This assessment tracks all inputs and outputs from the initial air capture to the final product.

The "cradle-to-gate" carbon footprint must account for the energy used in DAC, hydrogen production, and catalytic conversion. If the energy source is renewable, the net carbon balance becomes significantly negative.

Carbon sequestration through durable goods provides a unique economic incentive for the chemical industry. Unlike geological storage, which is a pure cost, plastic production generates a sellable product with market value.

The "Atmochemical" shift redefines the chemical industry's role from a major emitter to a primary carbon sink. This transformation is essential for meeting global net-zero targets and reversing historical atmospheric carbon increases.

Environmental groups emphasize the importance of ensuring that the hydrogen used is truly "green." Hydrogen produced from fossil fuels would negate the climate benefits of capturing CO2 from the atmosphere.

As the scale of DAC facilities increases, the cost per ton of captured carbon is expected to drop. This will make atmospheric feedstocks increasingly competitive with traditional petroleum-based sources for polymer manufacturing.

Policy Frameworks and the Future of Carbon Credits

Policy makers play a vital role in accelerating the transition to an atmochemical economy. Tax credits specifically for "Atmospheric Carbon Content" in durable goods could provide the necessary financial tailwinds.

Standardized labeling for carbon-negative products would allow consumers to make informed choices. This creates a market premium for goods that actively contribute to the removal of greenhouse gases from the air.

Carbon credit markets must evolve to recognize the long-term sequestration provided by durable polymers. Current frameworks often focus on forestation or geological storage, sometimes overlooking the potential of industrial carbon utilization.

International cooperation is required to establish common standards for atmospheric carbon accounting. This ensures that carbon-negative products can be traded globally without double-counting or fraudulent sequestration claims.

The shift from "Petrochemical" to "Atmochemical" represents a fundamental change in industrial philosophy. It moves society toward a regenerative model where industrial activity helps restore the planet's atmospheric balance.

Ultimately, the atmosphere will be viewed as a vast, renewable carbon mine that never runs dry. By tapping into this resource, we can build a sustainable future while cleaning up the legacy of the past.

We also Published

From our network :

- 98% of Global MBA Programs Now Prefer GRE Over GMAT Focus Edition

- Vite 6/7 'Cold Start' Regression in Massive Module Graphs

- https://www.themagpost.com/post/trump-political-strategy-how-geopolitical-stunts-serve-as-media-diversions

- Mastering DB2 12.1 Instance Design: A Technical Deep Dive into Modern Database Architecture

- Mastering DB2 LUW v12 Tables: A Comprehensive Technical Guide

- https://www.themagpost.com/post/analyzing-trump-deportation-numbers-insights-into-the-2026-immigration-crackdown

- 10 Physics Numerical Problems with Solutions for IIT JEE

- EV 2.0: The Solid-State Battery Breakthrough and Global Factory Expansion

- AI-Powered 'Precision Diagnostic' Replaces Standard GRE Score Reports

RESOURCES

- No query provided.

0 Comments