- Decarbonization: Eliminates the 1,500°C kiln requirement of traditional cement.

- Self-Healing: Integrated spores enable autogenous repair of structural micro-cracks.

- Economic Impact: Converts construction projects into high-value carbon credit generators.

On This Page

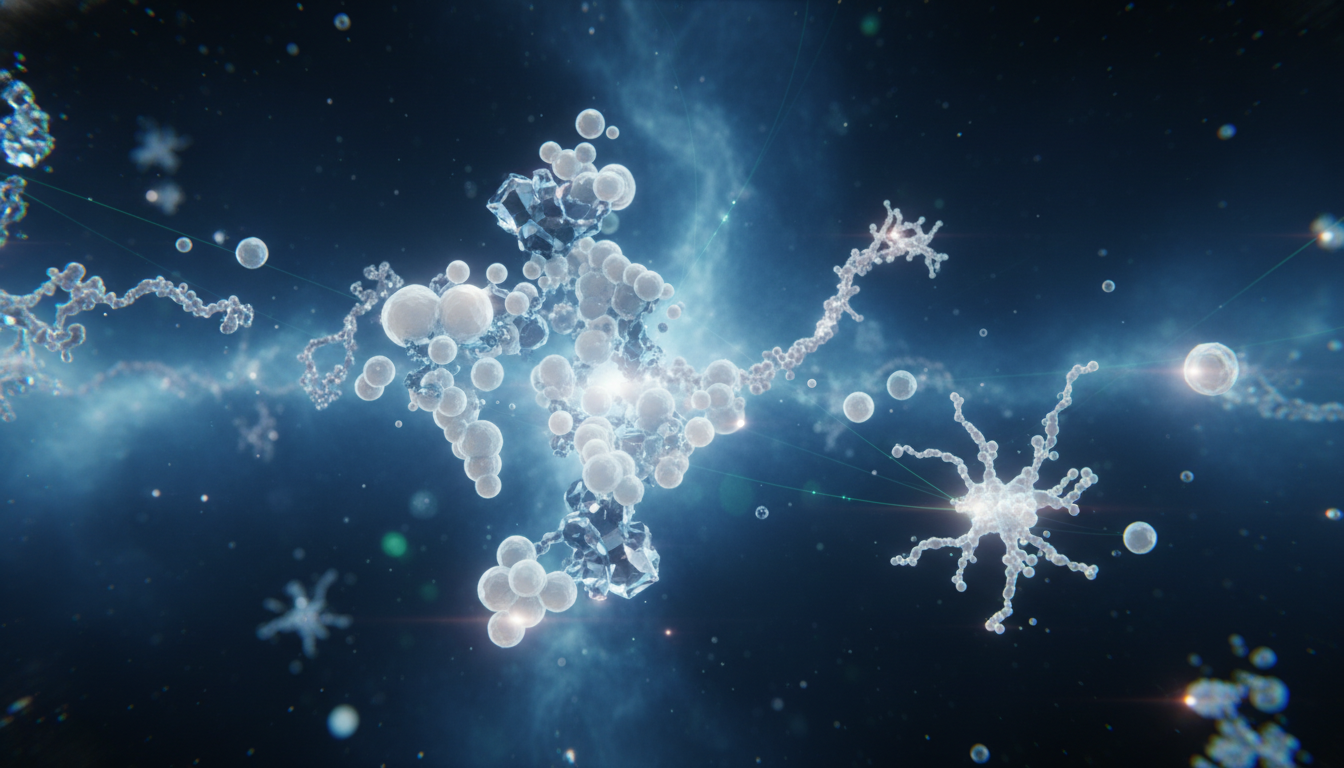

The Chemical Foundations of Bio-Cementation

Bio-cementation is a revolutionary chemical process that diverges significantly from the traditional manufacture of ordinary Portland cement. Instead of relying on the thermal decomposition of limestone, it utilizes biological pathways to bind aggregates together through mineral precipitation.

The core of this technology lies in the ability of specific microorganisms to alter their local chemical environment. By increasing the alkalinity and concentration of dissolved inorganic carbon, these microbes facilitate the crystallization of solid calcium carbonate in porous media.

This shift represents a transition from pyrotechnology to biotechnology within the construction sector. The chemical industry is now tasked with producing specialized nutrient broths and enzyme stabilizers rather than just bulk mineral additives for standard concrete mixes.

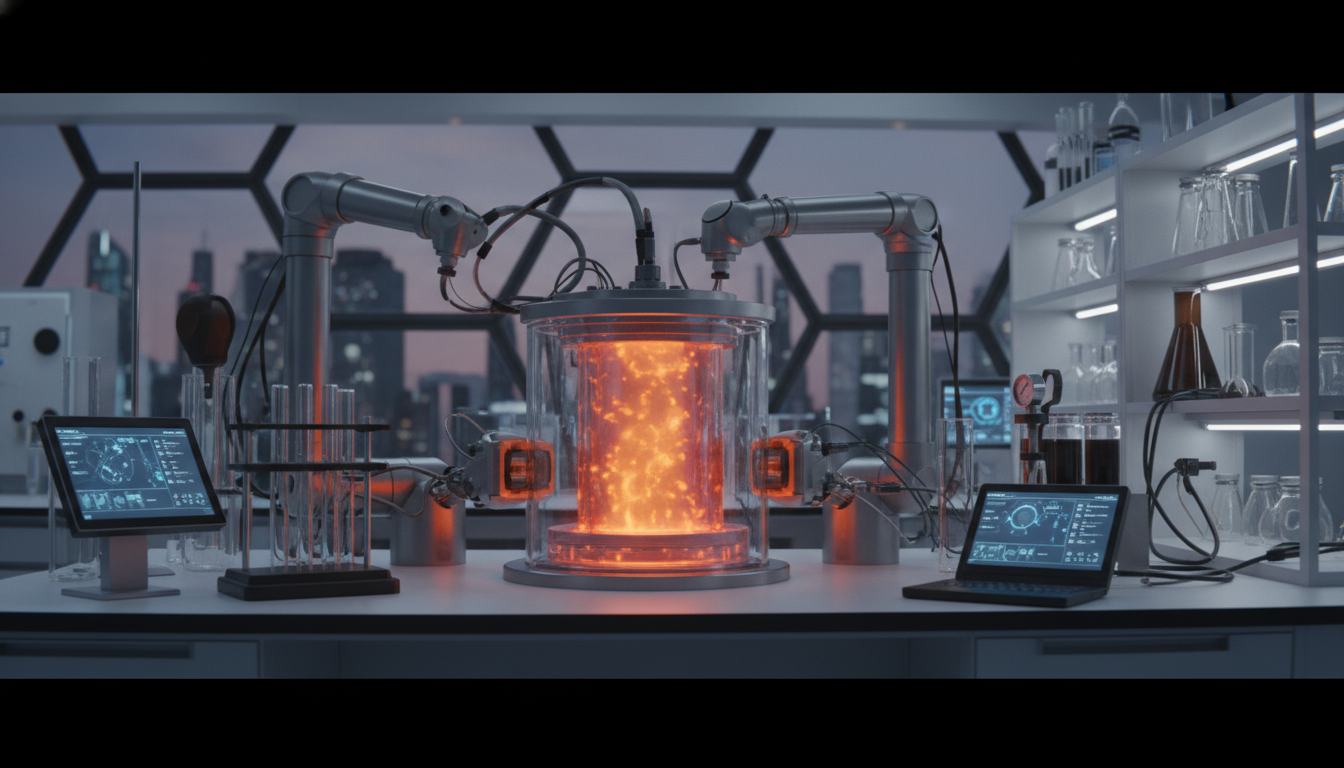

As we move toward 2026, the scalability of these biochemical reactions has improved through advanced bioreactor designs. These systems allow for the controlled cultivation of calcifying bacteria that are optimized for high-pressure and high-salinity construction environments.

The resulting bio-calcified material exhibits mechanical properties comparable to traditional low-grade concrete but with a significantly lower carbon footprint. This technical evolution marks the beginning of a new era in sustainable chemical engineering for global infrastructure.

Microbial Induced Carbonate Precipitation (MICP)

Microbial Induced Carbonate Precipitation, or MICP, is the primary chemical mechanism driving bio-cementation. It involves the metabolic activity of bacteria, most notably Sporosarcina pasteurii, which produces the urease enzyme to catalyze the hydrolysis of urea into ammonium.

The hydrolysis reaction increases the pH of the surrounding aqueous solution, which shifts the carbonate equilibrium toward the formation of carbonate ions. These ions then react with supplied calcium ions to form solid calcium carbonate crystals between soil particles.

The chemical efficiency of MICP depends on several factors, including bacterial cell density, urea concentration, and the availability of calcium sources. Optimizing these parameters is essential for ensuring uniform cementation throughout a large-scale structural element or soil mass.

Researchers are currently investigating various calcium sources, such as calcium chloride or calcium acetate, to minimize byproduct toxicity. The choice of calcium salt significantly influences the crystal morphology and the ultimate compressive strength of the bio-cemented matrix.

Furthermore, the spatial distribution of the precipitated calcite is governed by the transport of the bacterial suspension through the porous medium. Advanced fluid dynamics models are used to predict the precipitation patterns and prevent premature clogging of the injection points.

The Role of Urease Enzymes in Calcification

The urease enzyme acts as a high-efficiency biological catalyst that accelerates the rate of urea hydrolysis by a factor of nearly ##[10^{14}]##. This rapid reaction is necessary to create the localized supersaturation required for effective mineral precipitation.

Chemically, the active site of the urease enzyme contains nickel ions that facilitate the binding and activation of the urea molecule. Understanding this coordination chemistry allows engineers to develop synthetic mimics or stabilized enzyme formulations for site-specific applications.

The stability of the enzyme in the harsh environment of a construction site is a critical technical challenge. Factors such as extreme pH levels, heavy metal concentrations, and temperature fluctuations can denature the protein and halt the cementation process.

To mitigate these risks, the chemical industry is developing encapsulated enzyme systems. These micro-capsules protect the urease from environmental stressors until they are triggered by specific mechanical or chemical cues during the mixing and pouring of the concrete.

The integration of these enzymes into the construction workflow represents a significant leap in chemical precision. By controlling the timing and location of the enzymatic activity, engineers can tailor the material properties of the bio-cement to meet specific requirements.

Quantifying Carbon Sequestration and Energy Savings

The environmental benefit of bio-cementation is rooted in its fundamental thermodynamics. Traditional cement production requires the heating of calcium carbonate to approximately 1,500°C, releasing ##[CO_2]## as a direct byproduct of the chemical reaction and fuel combustion.

In contrast, bio-cementation occurs at ambient temperatures, effectively bypassing the energy-intensive kiln process. The chemical energy required for microbial growth and enzymatic activity is orders of magnitude lower than the thermal energy needed for calcination.

Furthermore, the MICP process actively sequesters atmospheric or industrial ##[CO_2]## by incorporating it into the mineral structure of the building material. This transforms the built environment from a carbon source into a permanent carbon sink for geological timescales.

Quantitative analysis of the carbon balance shows that bio-cement can achieve a negative net carbon footprint. This is calculated by subtracting the sequestered carbon and avoided emissions from the carbon costs associated with nutrient production and logistics.

The chemical industry’s role is expanding to include the management of these carbon credits. By providing certified bio-cementation precursors, chemical companies are enabling developers to meet increasingly stringent ESG (Environmental, Social, and Governance) targets and regulations.

Comparative Thermodynamics of Traditional vs. Bio-Cement

The enthalpy of formation for traditional clinker is significantly high due to the endothermic nature of limestone decarbonation. The reaction ##[CaCO_3 \rightarrow CaO + CO_2]## requires a substantial input of heat energy to proceed at industrial scales.

Bio-cementation operates through an exothermic pathway at low temperatures, where the Gibbs free energy change favors the spontaneous precipitation of calcite under alkaline conditions. This thermodynamic advantage translates directly into reduced operational costs and lower greenhouse gas emissions.

Analyzing the energy density of these processes reveals that bio-cementation uses biological "low-grade" energy more efficiently. Instead of high-grade fossil fuels, the process can utilize organic waste streams as a carbon and energy source for the bacteria.

The heat management in bio-cementation is also simpler, as there is no need for complex cooling systems or thermal recovery units. This allows for more flexible and decentralized production facilities, reducing the carbon costs associated with the transportation of heavy materials.

From a technical standpoint, the transition to bio-cementation requires a complete re-evaluation of the thermal profiles used in material science. Engineers must now focus on the metabolic heat of microbial populations rather than the radiant heat of industrial furnaces.

Mathematical Models for Precipitation Rates

Predicting the growth of bio-cement structures requires sophisticated mathematical models that integrate chemical kinetics with microbiology. These models typically follow a Monod-type kinetic equation to describe the rate of urea hydrolysis and subsequent mineral growth.

The rate of calcium carbonate precipitation ##[R_p]## can be expressed as a function of the saturation index and the available surface area for nucleation. This relationship is critical for determining the setting time and final density of the bio-concrete.

One of the primary challenges in modeling is accounting for the spatial heterogeneity of the microbial population. As the calcite precipitates, it can trap bacteria or block the flow of nutrients, leading to non-linear changes in the reaction rate over time.

Researchers use partial differential equations to simulate the reactive transport of urea and calcium ions through the pore network. These simulations help in designing injection strategies that ensure a homogeneous distribution of strength across the entire structural volume.

Advanced numerical methods, such as the Lattice Boltzmann Method, are employed to visualize the microscopic interaction between the fluid phase and the growing mineral crystals. This level of detail is essential for optimizing the chemical formulations used in large-scale projects.

Calculate the theoretical mass of ##[CO_2]## sequestered in 1,000 kg of pure bio-calcified material, assuming the material consists entirely of calcium carbonate (##[CaCO_3]##). Use the molar masses: ##[Ca=40.08, C=12.01, O=16.00]##.

Solution:

1. Molar mass of ##[CaCO_3 = 40.08 + 12.01 + (3 \times 16.00) = 100.09 \, g/mol]##.

2. Moles of ##[CaCO_3]## in 1,000 kg: ##[1,000,000 \, g / 100.09 \, g/mol \approx 9,991 \, mol]##.

3. Each mole of ##[CaCO_3]## sequesters one mole of ##[CO_3^{2-}]##, which is derived from ##[CO_2]##. Molar mass of ##[CO_2 = 12.01 + (2 \times 16.00) = 44.01 \, g/mol]##.

4. Mass of ##[CO_2]##: ##[9,991 \, mol \times 44.01 \, g/mol \approx 439,704 \, g]##.

Result: Approximately 440 kg of ##[CO_2]## is sequestered per 1,000 kg of bio-cement.

Recommended Reads

Engineering Durability and Self-Healing Mechanisms

One of the most compelling technical advantages of bio-cementation is its inherent capacity for self-healing. Traditional concrete is prone to micro-cracking due to shrinkage, thermal stress, or mechanical loading, which eventually leads to structural failure.

In bio-cemented structures, specialized chemical spores are embedded within the matrix during the initial construction. These spores remain dormant as long as the concrete is intact and dry, acting as a latent biological insurance policy for the building.

When a crack forms, moisture and oxygen penetrate the material, reaching the embedded spores. This change in the local chemical environment triggers the germination of the bacteria, which then begin the process of mineral precipitation to fill the void.

The chemical reaction for self-healing is identical to the initial cementation process, resulting in the formation of new calcium carbonate crystals. These crystals bridge the gap of the crack, restoring the material's water-tightness and a portion of its structural integrity.

This "autogenous healing" significantly extends the service life of infrastructure and reduces the need for expensive manual repairs. It represents a move toward "living" materials that can autonomously respond to damage and maintain their functional performance over decades.

Autogenous Healing and Structural Longevity

The effectiveness of autogenous healing is measured by the maximum crack width the bacteria can successfully seal. Current chemical formulations allow for the repair of cracks up to 0.5 mm to 0.8 mm in width, which is sufficient for most structural applications.

The chemical industry is focusing on optimizing the "shelf-life" of these embedded spores. Ensuring that the bacteria remain viable for 50 to 100 years within the highly alkaline environment of concrete is a significant molecular biology and chemical engineering feat.

In addition to sealing cracks, the precipitated calcite reduces the permeability of the concrete. This prevents the ingress of corrosive agents like chlorides and sulfates, which are the primary causes of steel reinforcement corrosion in traditional reinforced concrete.

The longevity of bio-cemented structures is thus enhanced through two chemical pathways: active repair and passive protection. This dual-action mechanism makes bio-cement particularly attractive for marine infrastructure and underground tunnels where maintenance is difficult and costly.

Experimental data from long-term durability tests show that bio-healed concrete maintains its compressive strength better than traditional concrete after repeated freeze-thaw cycles. This resilience is a key selling point for urban developers looking to minimize life-cycle costs.

Chemical Spore Integration in Concrete Matrices

Integrating biological components into a mineral matrix requires careful chemical compatibility studies. The spores must be robust enough to survive the mechanical mixing process and the high pH (often above 12) of the initial cement hydration phase.

To protect the spores, chemical engineers use various encapsulation techniques, such as lightweight expanded clay aggregates or polymers. These carriers provide a micro-environment that buffers the pH and supplies the necessary nutrients for the bacteria once they are activated.

The concentration of spores and nutrients must be precisely balanced to ensure effective healing without compromising the initial strength of the concrete. Too much organic matter can interfere with the mineral bonding, while too little will result in insufficient healing capacity.

Advancements in synthetic biology are allowing for the creation of "designer" spores with enhanced resistance to chemical stressors. These genetically modified organisms are tailored to thrive in specific cement chemistries, further broadening the applicability of the technology.

The production of these specialized chemical-biological additives is becoming a high-margin sector for the chemical industry. By moving away from commodity chemicals toward high-performance bio-additives, companies can capture more value in the green construction market.

If the rate of calcite precipitation is ##[0.05 \, mm^3/hour]## per active bacterial colony, and a crack of volume ##[10 \, mm^3]## is detected, how many active colonies are required to seal the crack within 48 hours?

Solution:

1. Required total precipitation in 48 hours: ##[10 \, mm^3]##.

2. Precipitation per colony in 48 hours: ##[0.05 \, mm^3/hour \times 48 \, hours = 2.4 \, mm^3]##.

3. Number of colonies: ##[10 / 2.4 \approx 4.17]##.

Result: At least 5 active colonies are required to ensure the crack is sealed within the timeframe.

Economic and Regulatory Shifts in the Global Market

The transition to bio-cementation is not only a technical shift but a profound economic one. As global carbon taxes rise, the financial burden of using traditional high-emission cement is becoming unsustainable for many large-scale infrastructure projects.

Bio-cementation offers a way to hedge against these future costs by locking in "negative-carbon" certifications at the time of construction. This creates a new asset class where the building itself serves as a repository for valuable carbon credits.

Regulatory bodies in major metropolitan areas are beginning to recognize the benefits of these materials. Building codes are being updated to provide fast-track permitting for projects that utilize certified bio-chemical construction methods and sequestered carbon materials.

The chemical industry is at the center of this shift, acting as the primary provider of the specialized reagents and biological catalysts. This creates a strategic dependency between the chemical sector and the global construction and real estate markets.

Investment is pouring into startups and established chemical giants that are leading the charge in bio-cementation research. The goal is to reach price parity with traditional concrete, making the "green" choice the standard economic choice for every engineer.

Decarbonization as a Financial Catalyst

The financial viability of bio-cementation is increasingly tied to the price of carbon in international markets. When the cost of emitting a ton of ##[CO_2]## exceeds the premium for bio-cement, the market will experience an immediate and total shift.

Chemical companies are leveraging this by offering "carbon-inclusive" pricing models. In these models, the cost of the bio-cementation chemicals is offset by the value of the carbon credits generated by the completed structure, lowering the upfront capital requirement.

This financial innovation is attracting institutional investors who are looking for green infrastructure projects with long-term stability. The durability and self-healing properties of bio-cement further enhance the risk profile of these investments by reducing future maintenance liabilities.

Furthermore, the use of bio-cement can improve a corporation's ESG rating, which is increasingly used to determine access to capital and interest rates. This creates a powerful incentive for developers to specify bio-calcified materials in their project tenders.

The chemical industry’s ability to provide transparent and verifiable data on the carbon sequestration of their products is crucial. Blockchain technology is often used to track the chemical precursors from the factory to the construction site, ensuring the integrity of the carbon claims.

Future Perspectives on Urban Carbon Sequestration

Looking forward, the vision for bio-cementation extends beyond simple building blocks to entire "living cities." In this future, the urban environment acts as a massive chemical reactor that continuously pulls ##[CO_2]## from the atmosphere and stores it in the infrastructure.

The chemical industry will likely evolve into a service-based model, where companies manage the biological health and carbon-sequestration performance of buildings over their entire lifespan. This represents a significant shift from the traditional "sell-and-forget" commodity chemical model.

Research into synthetic biology may lead to bacteria that can not only precipitate calcite but also capture other pollutants, such as nitrogen oxides or volatile organic compounds. This would turn every wall and pavement into an active air purification system.

The integration of sensors within the bio-cemented matrix will allow for real-time monitoring of the material's chemical state. This data-driven approach to construction will enable predictive maintenance and further optimize the carbon sequestration rates of urban centers.

Ultimately, bio-cementation is a testament to the power of merging chemistry, biology, and engineering. It provides a technical pathway to a sustainable future where the act of building contributes to the restoration of the planet's atmospheric balance.

The rate of urea hydrolysis by urease follows Michaelis-Menten kinetics: ##[v = \frac{V_{max}[S]}{K_m + [S]}]##. If ##[V_{max} = 0.8 \, mmol/L \cdot min]##, ##[K_m = 5 \, mmol/L]##, and the urea concentration ##[[S]]## is ##[15 \, mmol/L]##, calculate the reaction rate ##[v]##.

Solution:

1. Substitute the values into the formula: ##[v = \frac{0.8 \times 15}{5 + 15}]##.

2. Calculate the numerator: ##[0.8 \times 15 = 12]##.

3. Calculate the denominator: ##[5 + 15 = 20]##.

4. Divide: ##[12 / 20 = 0.6]##.

Result: The reaction rate is ##[0.6 \, mmol/L \cdot min]##.

We also Published

From our network :

- AI-Powered 'Precision Diagnostic' Replaces Standard GRE Score Reports

- EV 2.0: The Solid-State Battery Breakthrough and Global Factory Expansion

- 10 Physics Numerical Problems with Solutions for IIT JEE

- Mastering DB2 12.1 Instance Design: A Technical Deep Dive into Modern Database Architecture

- Vite 6/7 'Cold Start' Regression in Massive Module Graphs

- https://www.themagpost.com/post/trump-political-strategy-how-geopolitical-stunts-serve-as-media-diversions

- 98% of Global MBA Programs Now Prefer GRE Over GMAT Focus Edition

- Mastering DB2 LUW v12 Tables: A Comprehensive Technical Guide

- https://www.themagpost.com/post/analyzing-trump-deportation-numbers-insights-into-the-2026-immigration-crackdown

RESOURCES

- No query provided.

0 Comments